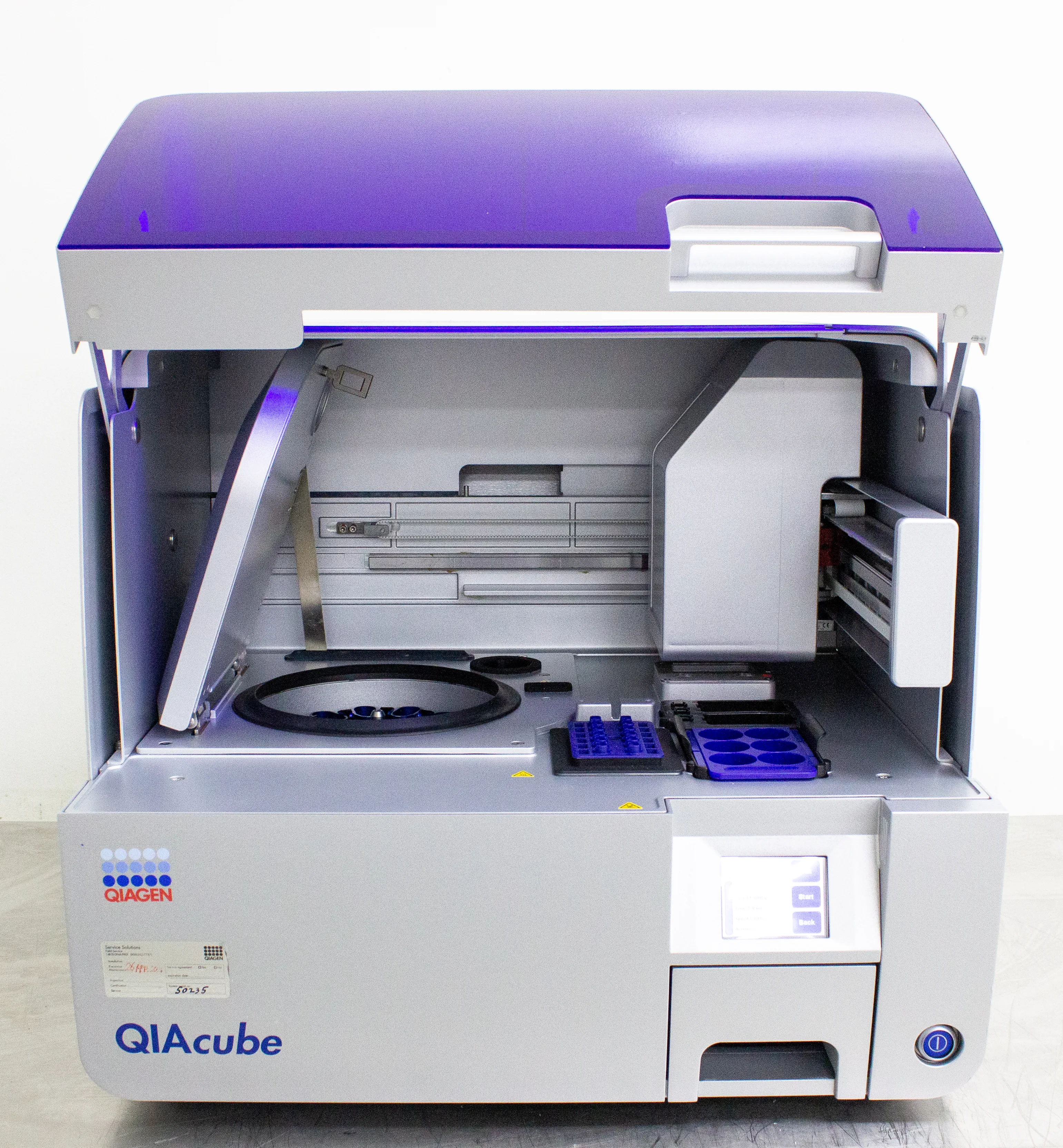

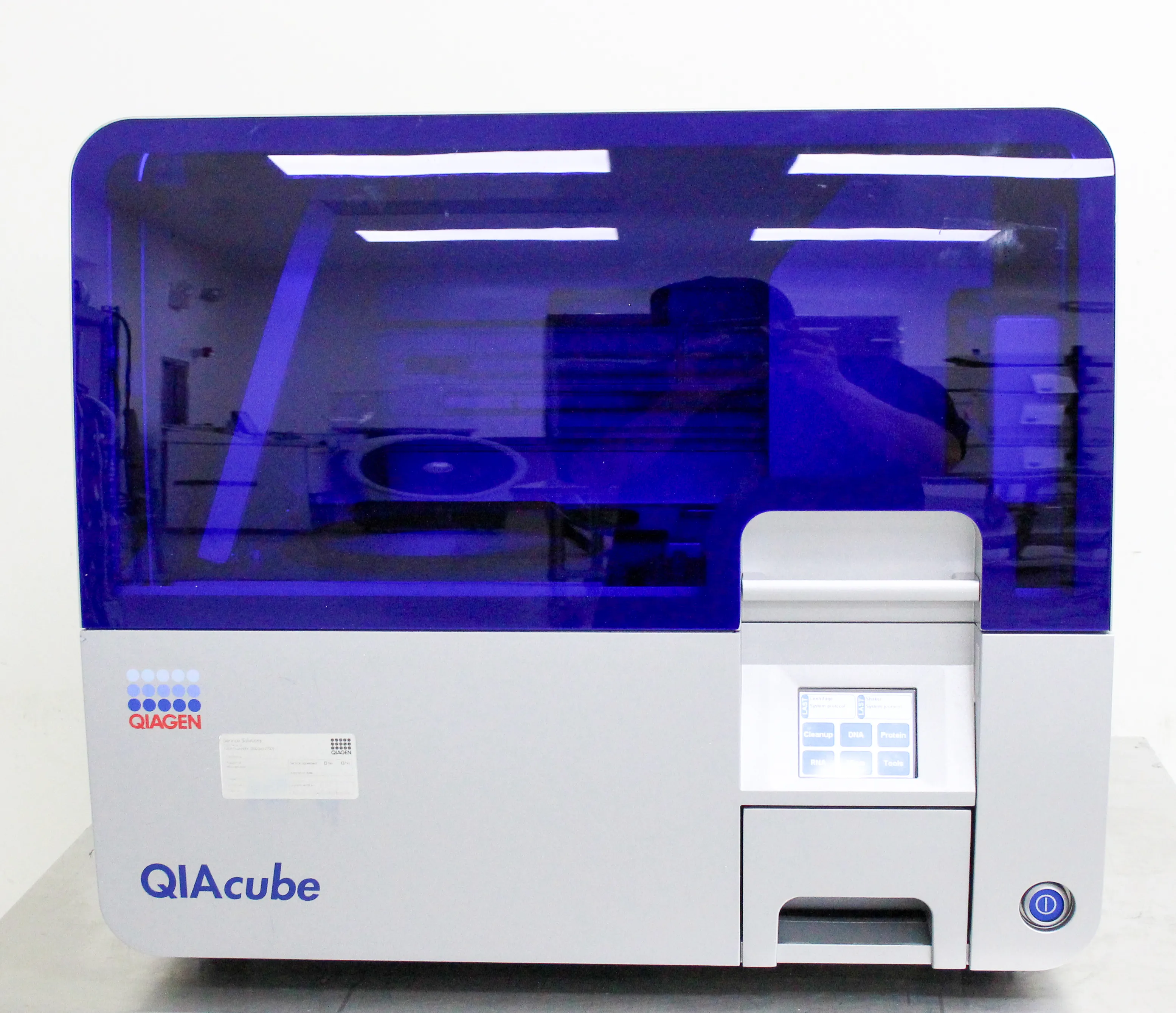

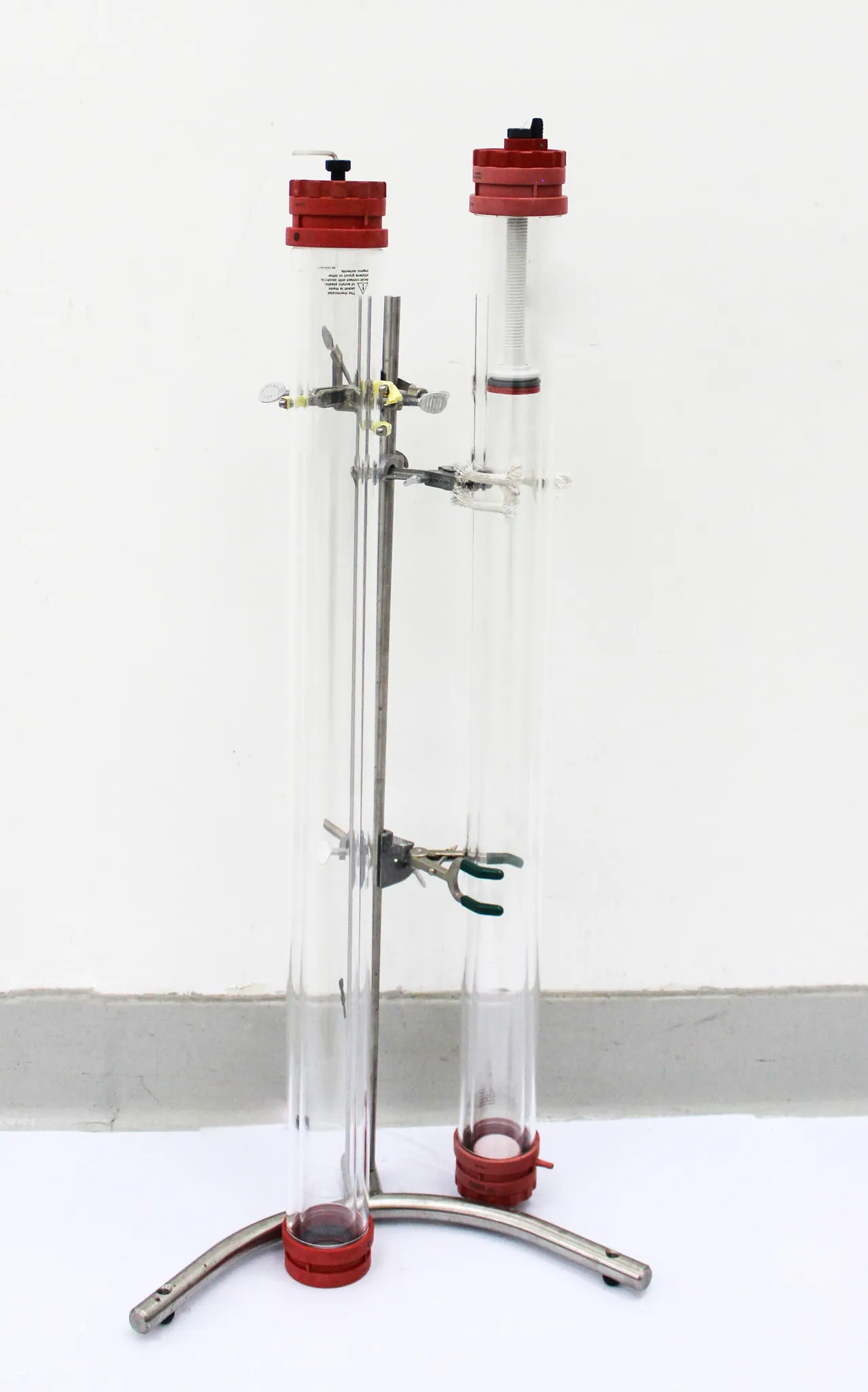

Process Columns are vital in industries such as chemical processing, pharmaceuticals, and food production for separating and purifying mixtures. These columns utilize techniques like distillation, absorption, and chromatography to achieve desired product qualities. Explore a range of new and used process columns to meet your production needs.

Process Columns

Price Filter

$95.00 - $750,000.00Product Region

Product Condition

Product Warranty

Browse By Category

Technikrom HPLC System with Wedgewood 660-S UV and 680 Dual Beam VIS/NIR Detectors

Thermo Scientific T3 Microplate Thermotor CarouselS02128

Question & Answers For:

Process Columns

Past Questions, Helpful Answers.

What are process columns used for?

Process columns are used in industries like chemical processing, pharmaceuticals, and food production to separate and purify mixtures. They employ techniques such as distillation, absorption, and chromatography to achieve the desired product quality.

How do process columns work?

Process columns work by utilizing physical or chemical separation techniques. For example, in distillation columns, components are separated based on boiling points, while absorption columns remove specific substances from gas or liquid streams using a solvent.

What materials are process columns made from?

Process columns are commonly made from stainless steel, carbon steel, or specialty alloys depending on the process requirements, chemical compatibility, and operating conditions such as pressure and temperature.

How do I choose the right process column for my application?

The right process column depends on factors such as the type of separation required, operating pressure and temperature, chemical compatibility, flow rate, and efficiency needs. Consulting with a process engineer can help determine the best option.

What are the key differences between new and used process columns?

New process columns offer the latest technology and can be customized, while used process columns are often more cost-effective and available for immediate use. Used columns should be inspected for wear and compatibility with your process.

Can process columns be customized for specific applications?

Yes, process columns can be designed with specific internals, materials, and configurations to meet unique processing requirements. Customization ensures optimal separation efficiency and performance.

What types of industries commonly use process columns?

Industries such as chemical manufacturing, pharmaceuticals, food and beverage processing, petroleum refining, and environmental treatment widely use process columns for various separation and purification processes.

How do I maintain a process column for long-term efficiency?

Regular inspections, cleaning, and monitoring of operating parameters such as temperature, pressure, and flow rates help maintain efficiency. Proper maintenance prevents fouling, scaling, and operational failures.