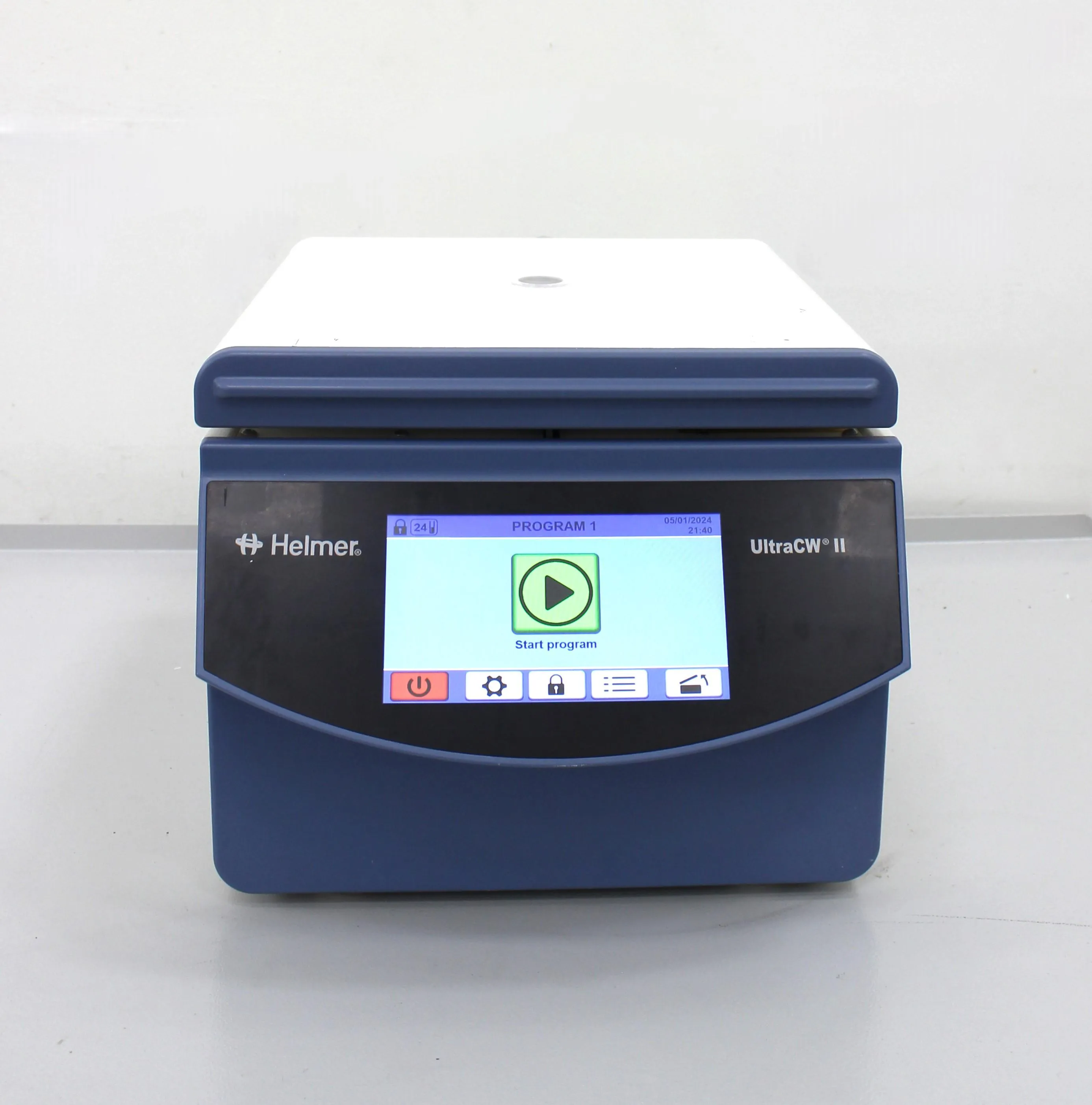

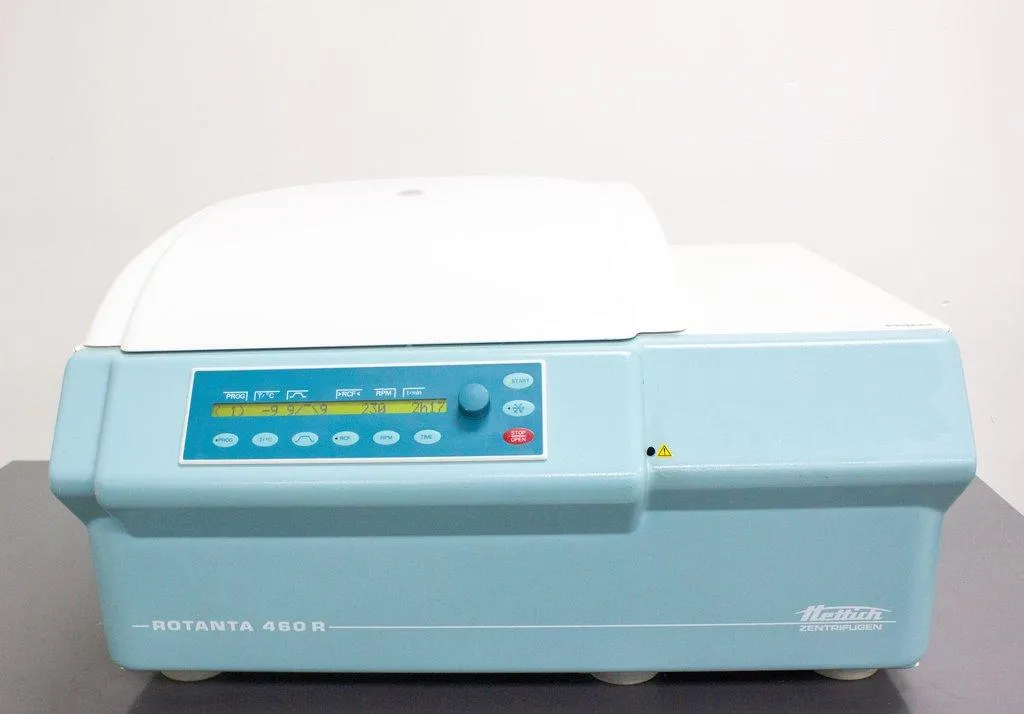

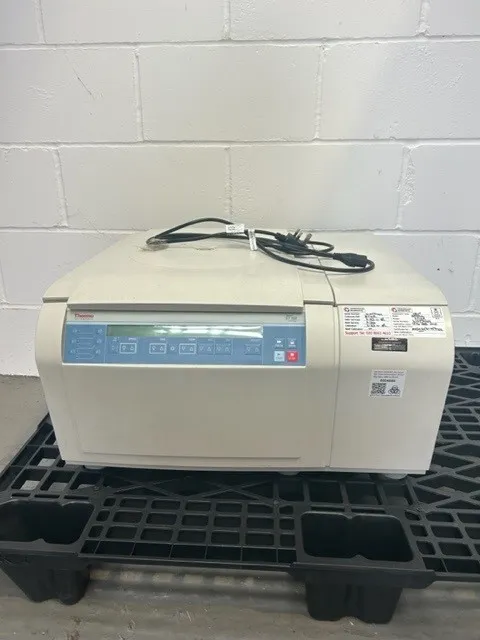

Process Centrifuges are essential for separating fluids and solids in various industries, including pharmaceuticals, biotechnology, and food processing. These machines utilize high-speed rotation to efficiently separate components based on density. Explore a variety of new and used process centrifuges to suit your operational requirements.

Process Centrifuges

Price Filter

$100.00 - $75,000.00Product Region

Product Condition

Product Warranty

Browse By Category

Millipore Mobius Power Mix 1000L P/N MXRJ1000TLA Single-Use Mixing System

Thermo Fisher Scientific Sorvall ST 16R Benchtop Centrifuge

3M Purification Inc. Cartridge Filter Housing Model 12ZPB1 / 4547301

Question & Answers For:

Process Centrifuges

Past Questions, Helpful Answers.

How does a process centrifuge work?

A process centrifuge operates by spinning at high speeds to separate components based on density. Heavier solids settle at the outer edges, while lighter liquids remain closer to the center, enabling efficient separation.

What industries commonly use process centrifuges?

Process centrifuges are widely used in pharmaceuticals, biotechnology, food processing, chemical manufacturing, and wastewater treatment for separating solids from liquids or different liquid phases.

What factors should be considered when selecting a process centrifuge?

Key factors include processing capacity, type of separation required (solid-liquid or liquid-liquid), material compatibility, automation level, and energy efficiency.

What types of process centrifuges are available?

Common types include decanter centrifuges (continuous solid-liquid separation), disc stack centrifuges (high-speed liquid separation), and basket centrifuges (batch processing for solid-liquid separation).

How do I determine the right centrifuge speed for my application?

The required speed depends on the density difference between components and the desired separation efficiency. Higher speeds provide better separation but must be balanced with material properties and operational needs.

How do I maintain a process centrifuge for optimal performance?

Regular maintenance includes cleaning, inspecting for wear, ensuring proper lubrication, and monitoring vibration levels to prevent damage and maintain efficiency.

Can process centrifuges handle different types of materials?

Yes, but material compatibility must be considered. Some centrifuges are designed for specific applications, such as pharmaceutical-grade models with strict hygiene standards or food-grade options with corrosion-resistant materials.

What are the safety considerations when using a process centrifuge?

Operators should follow safety guidelines, including proper loading, avoiding over-speeding, using protective barriers, and ensuring regular maintenance to prevent mechanical failures.

How energy-efficient are process centrifuges?

Energy efficiency varies by design and operational settings. Some models include energy-saving features such as variable-speed drives and automatic controls to optimize power usage.

Can process centrifuges be integrated into an automated production line?

Yes, many modern centrifuges offer automation capabilities, including programmable controls and real-time monitoring, allowing seamless integration into industrial processes.