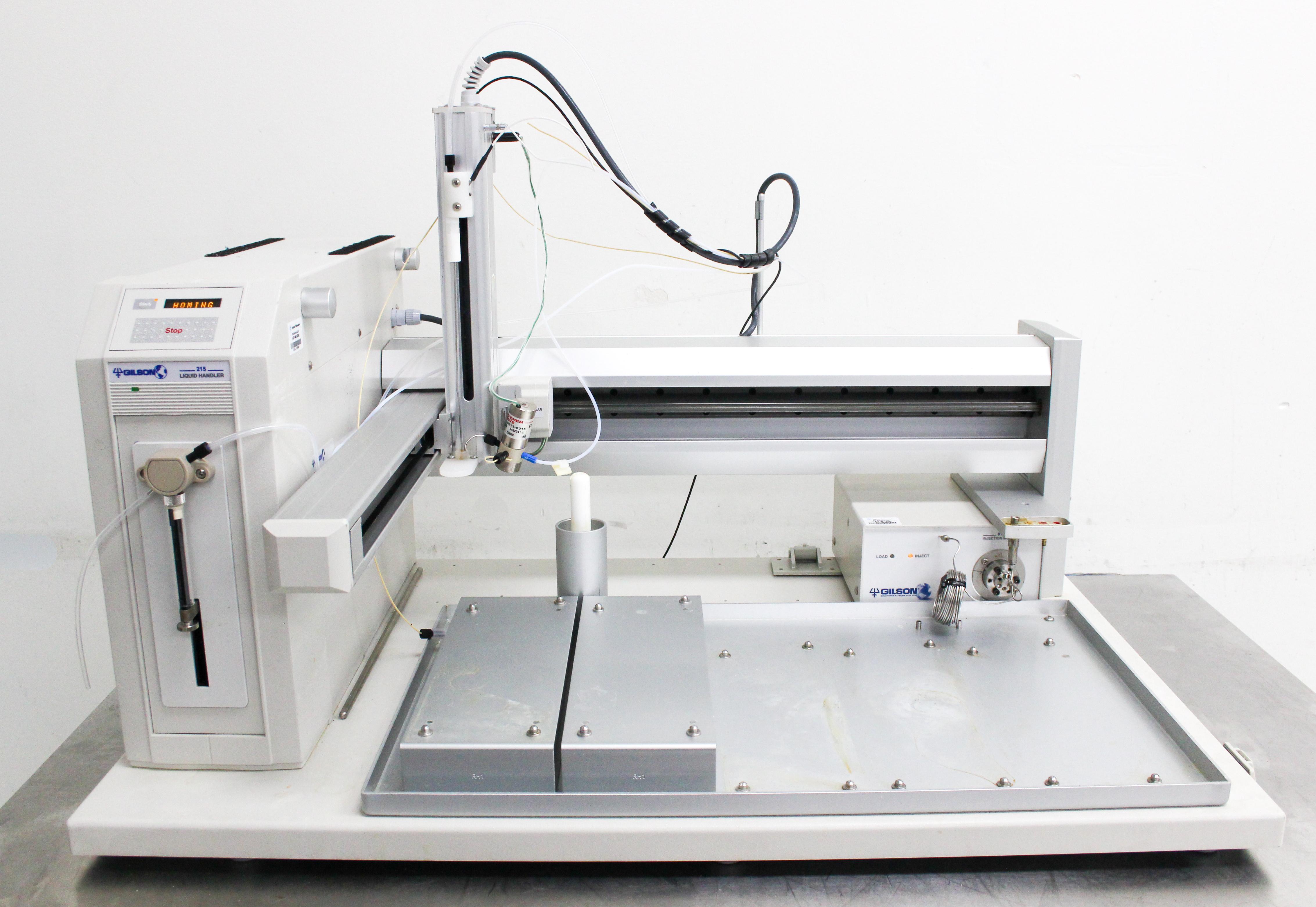

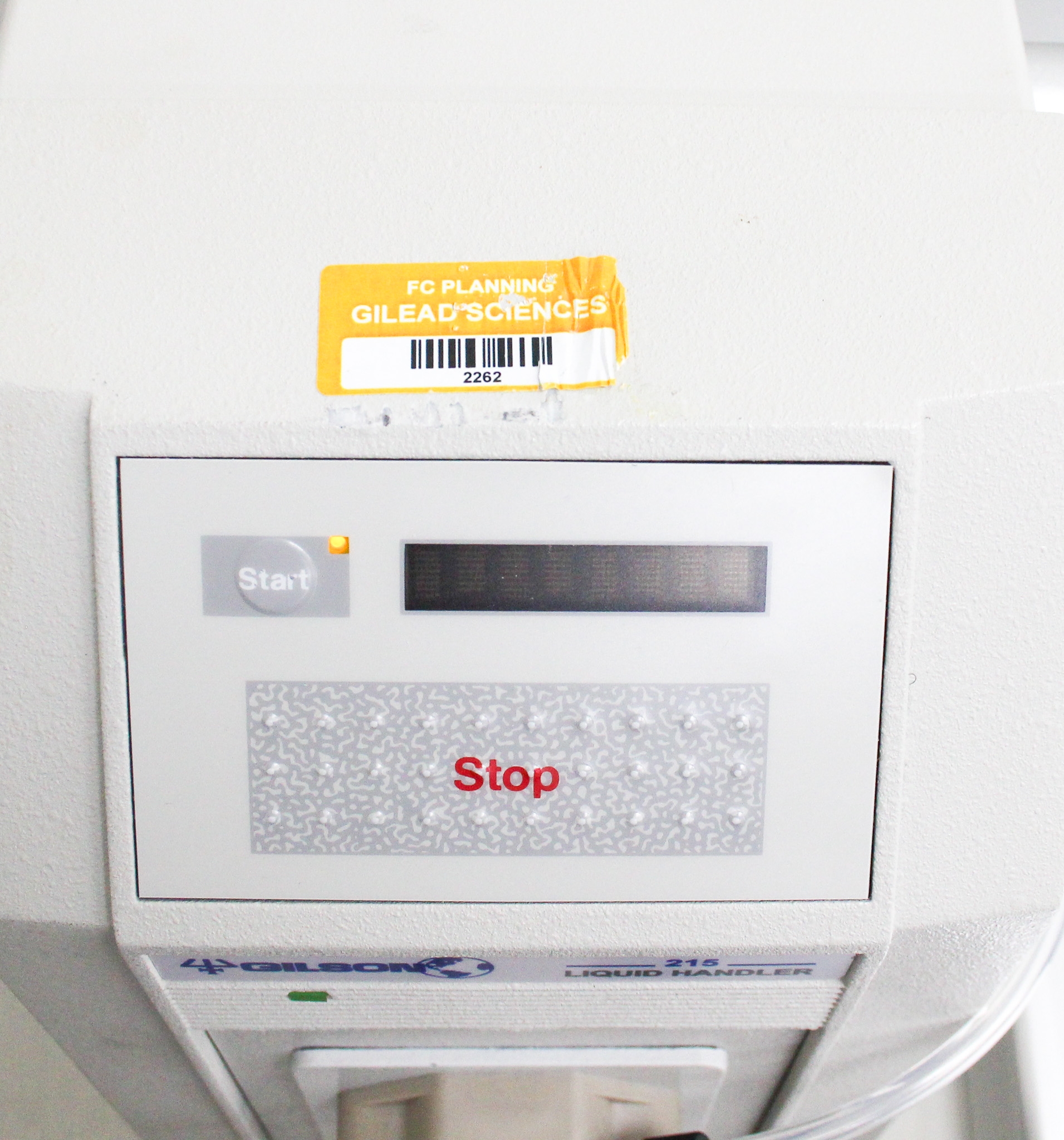

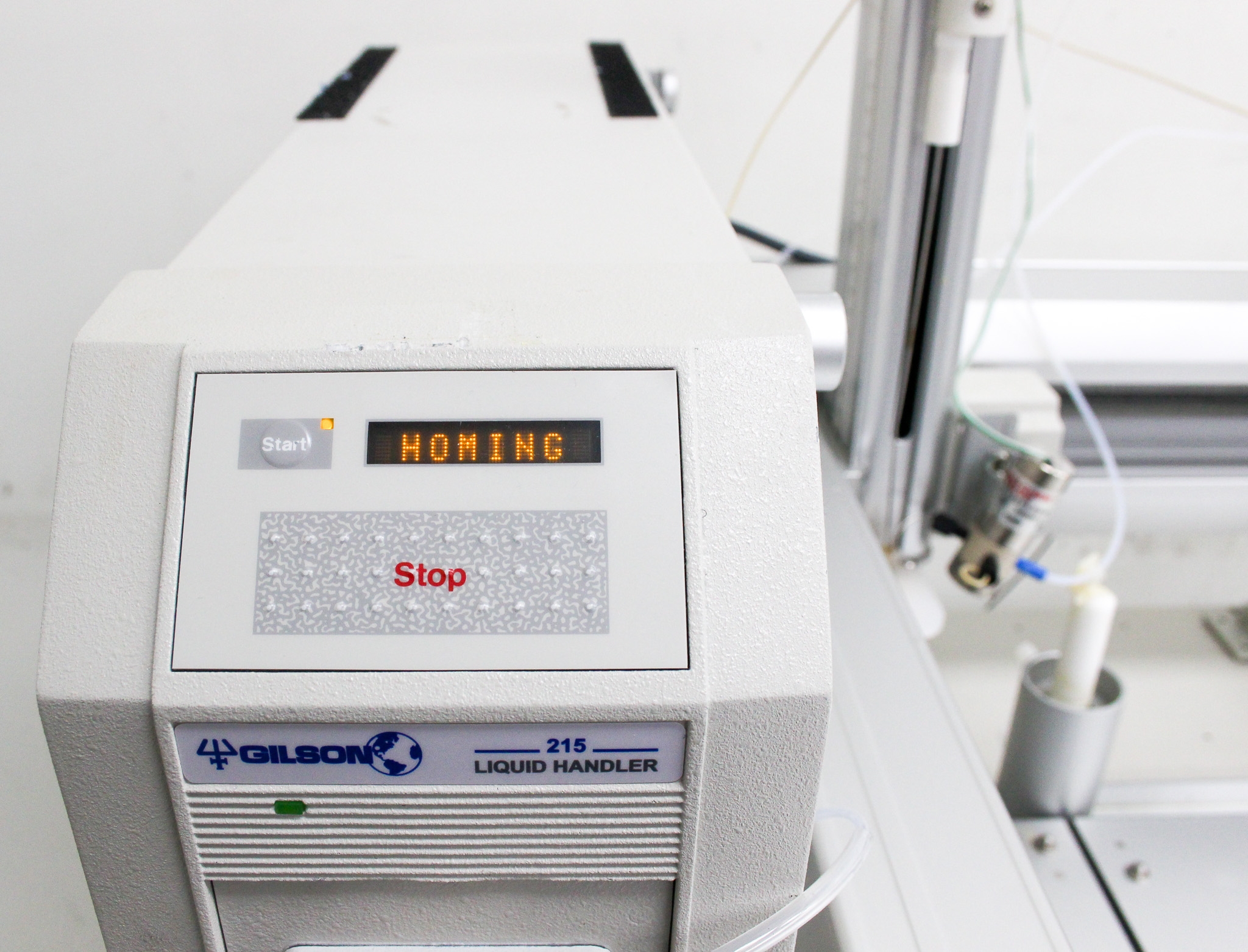

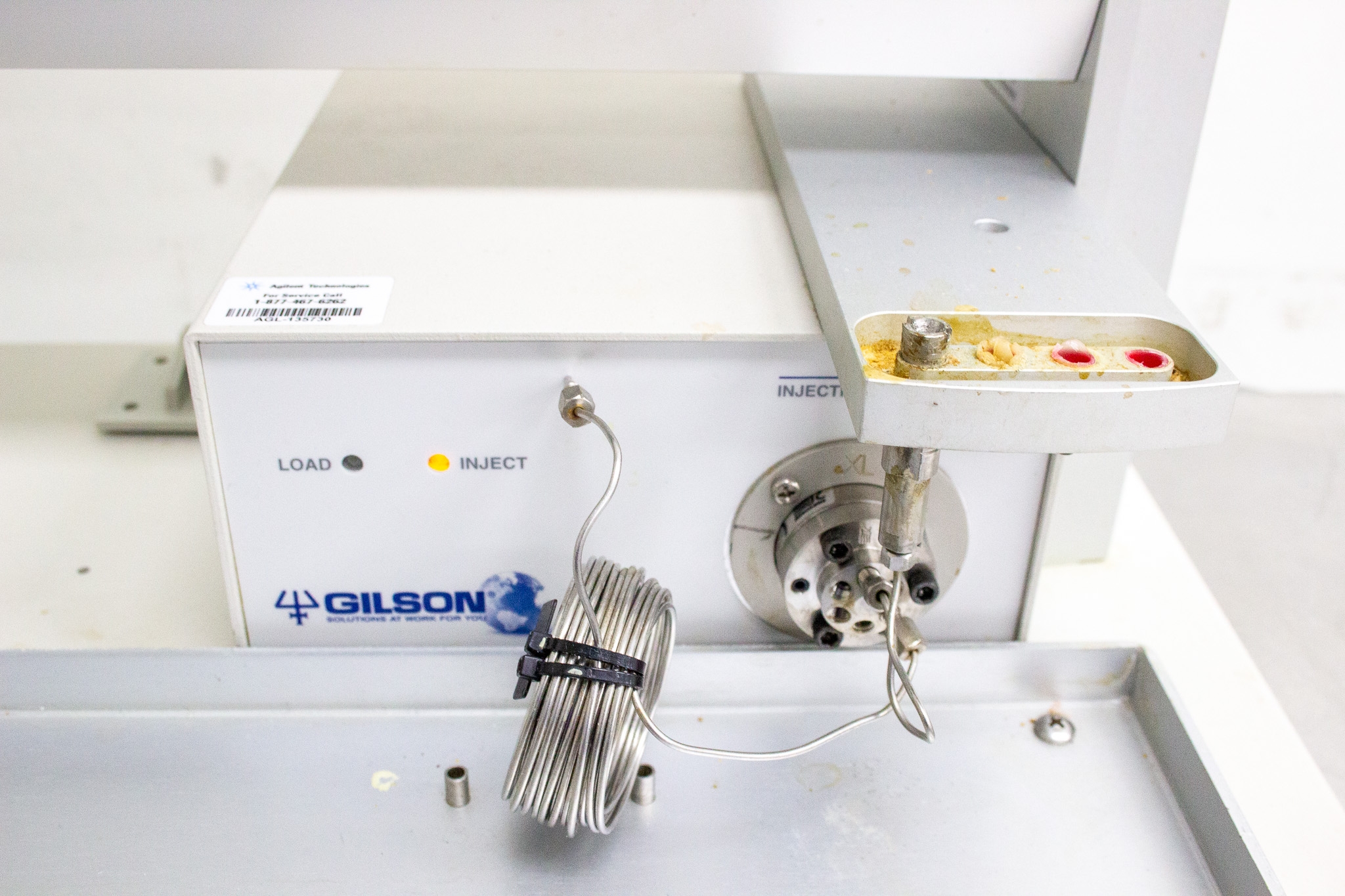

Gilson Nebula 215 Automated Liquid Handler w/ 819 Injection Module 50Hz

Gilson

Details

-

CategoryLiquid Handling

-

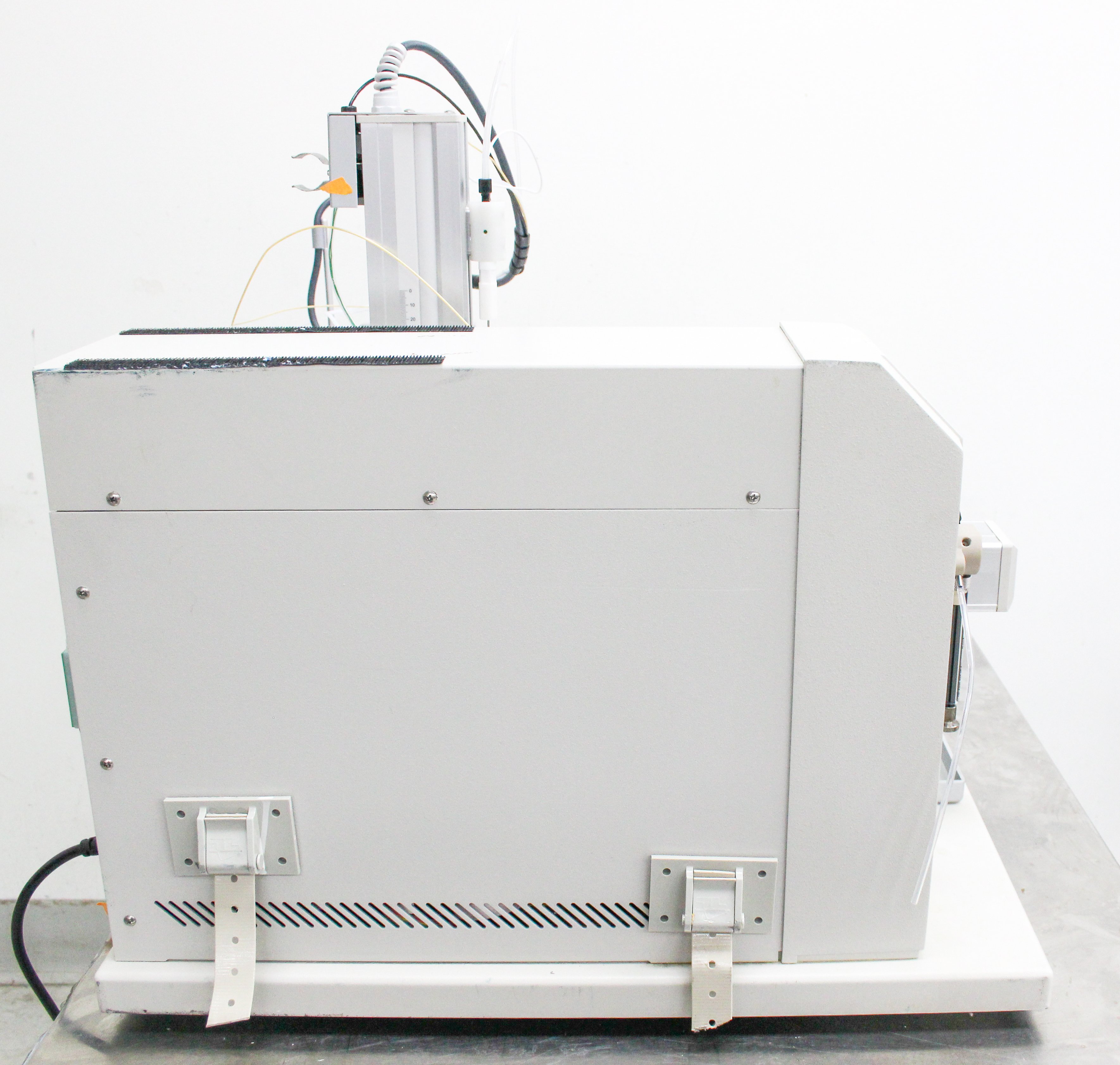

Dimension24.0in x 34.0in x 24.0in

-

Serial250M7123

-

Shipping TypeFedEx Ground

-

ManufacturingDoes Not Apply

-

Voltage / Hertz120V/220V / 50Hz/60Hz

Description

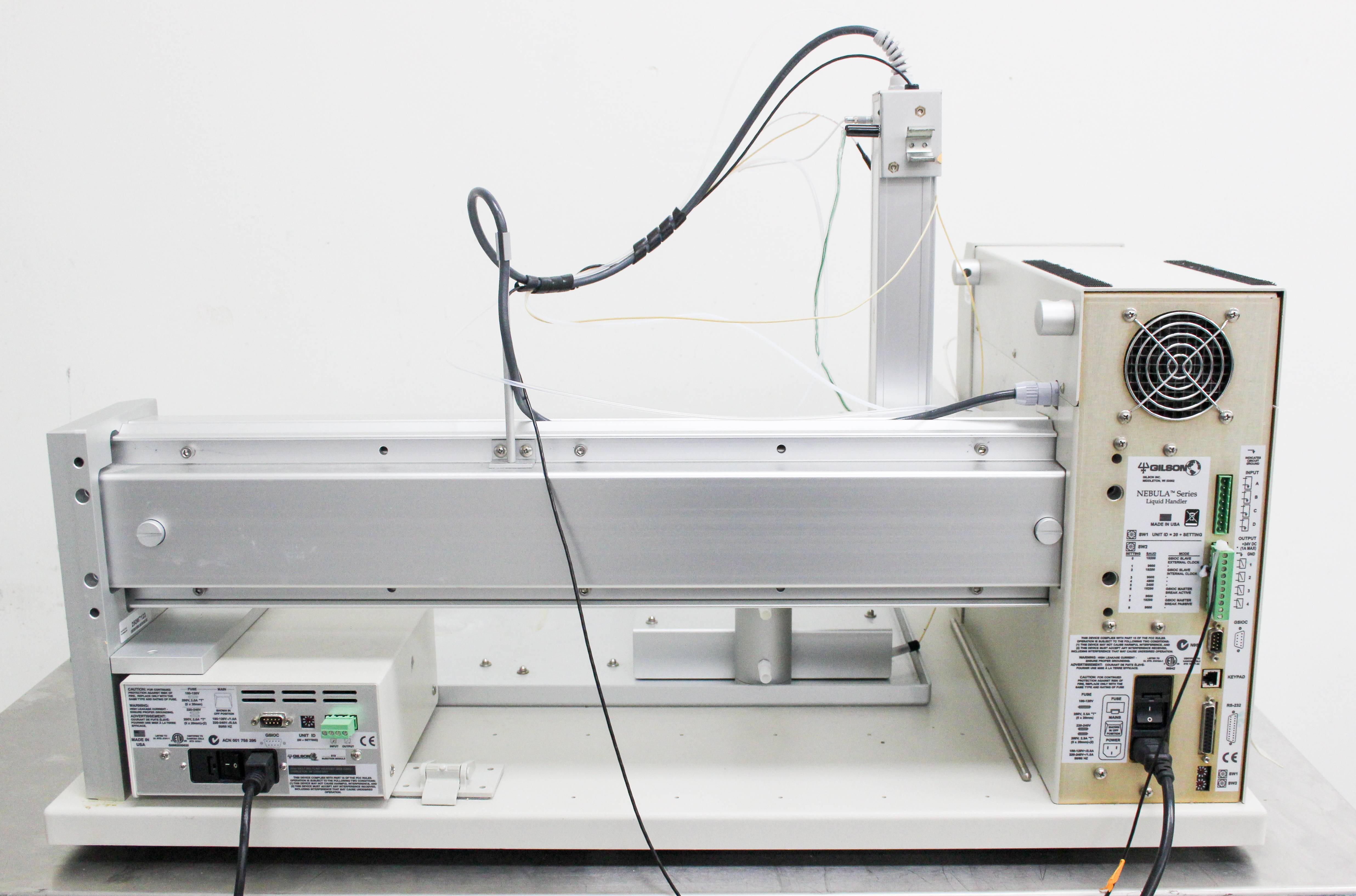

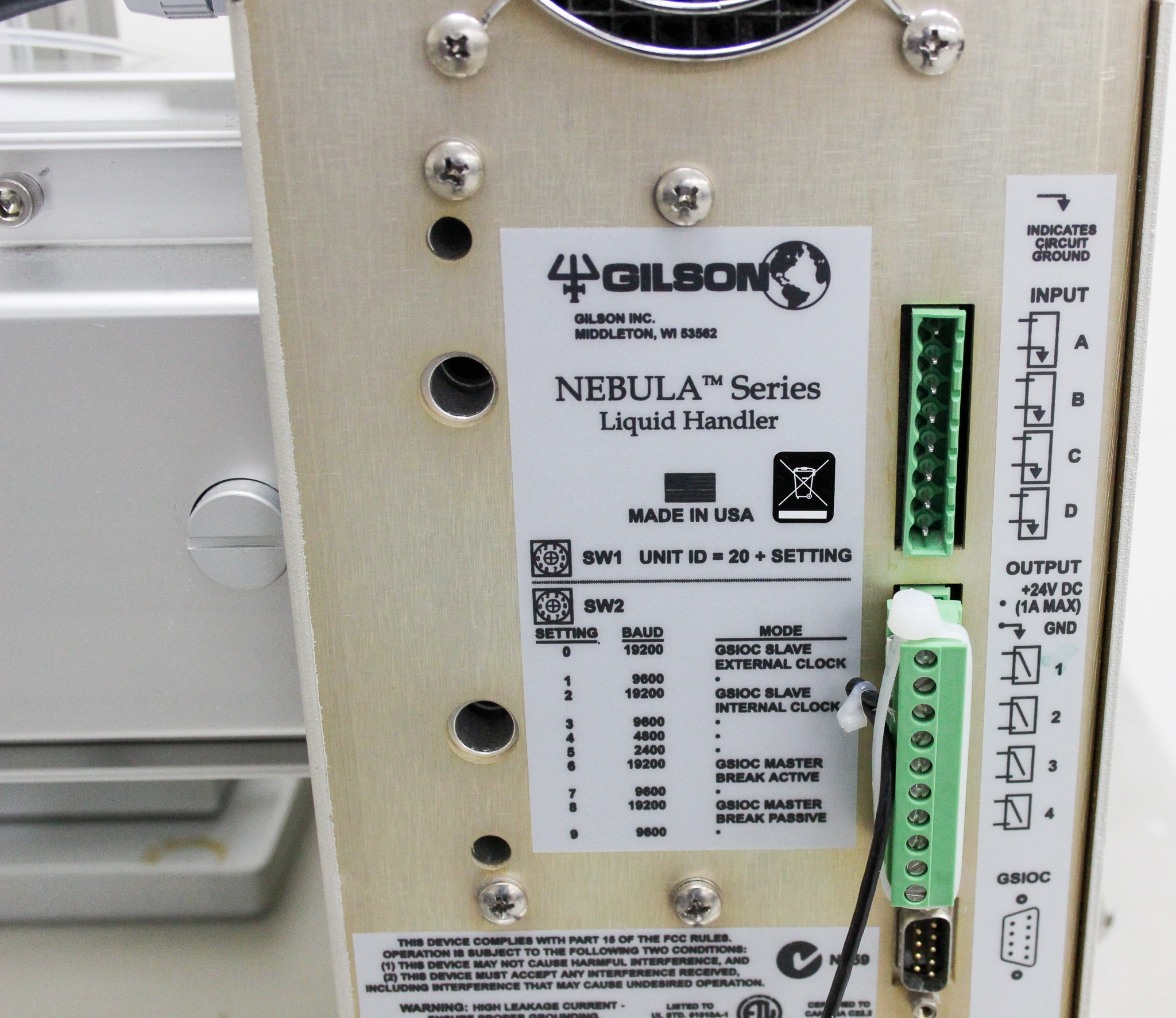

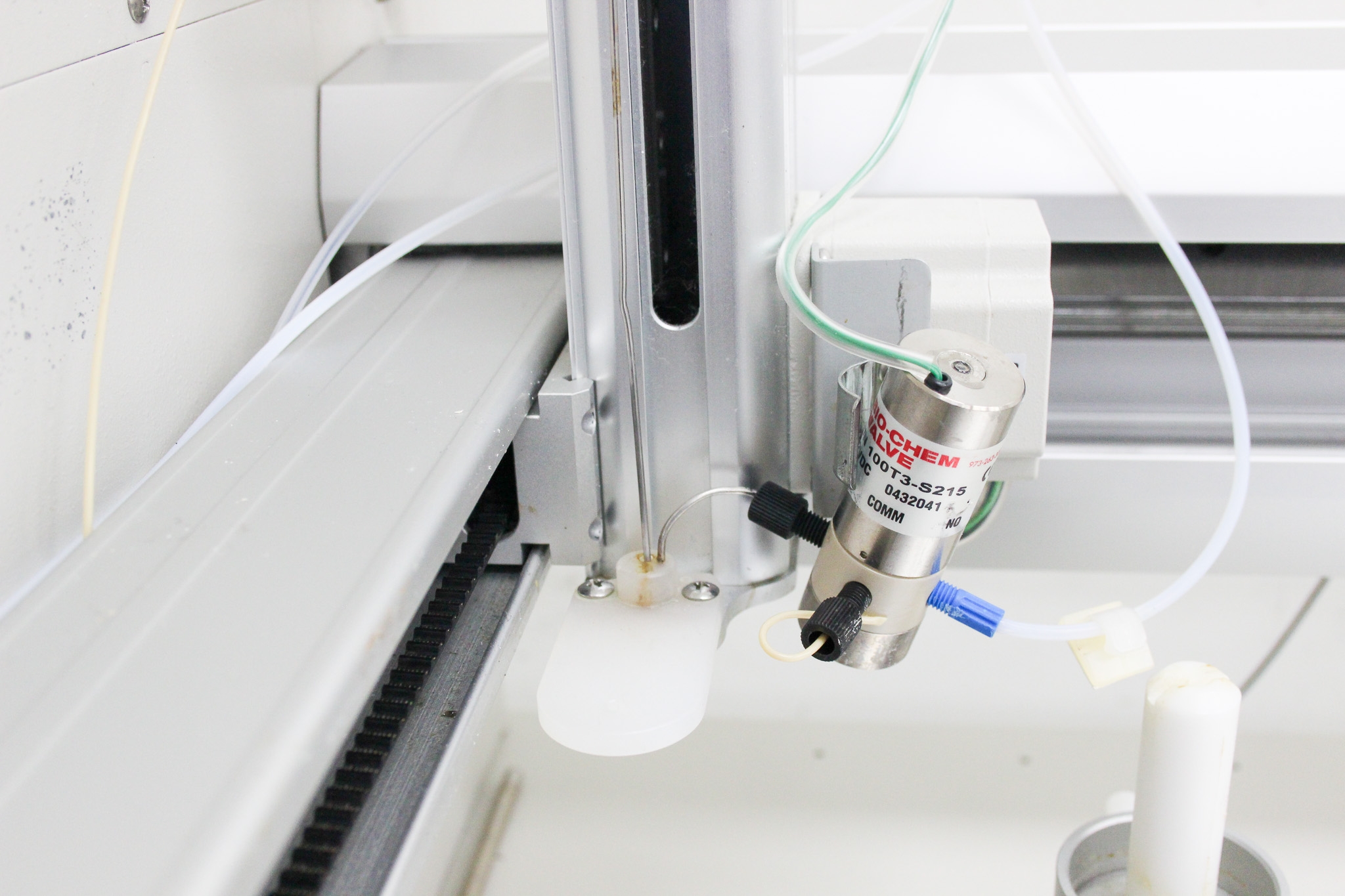

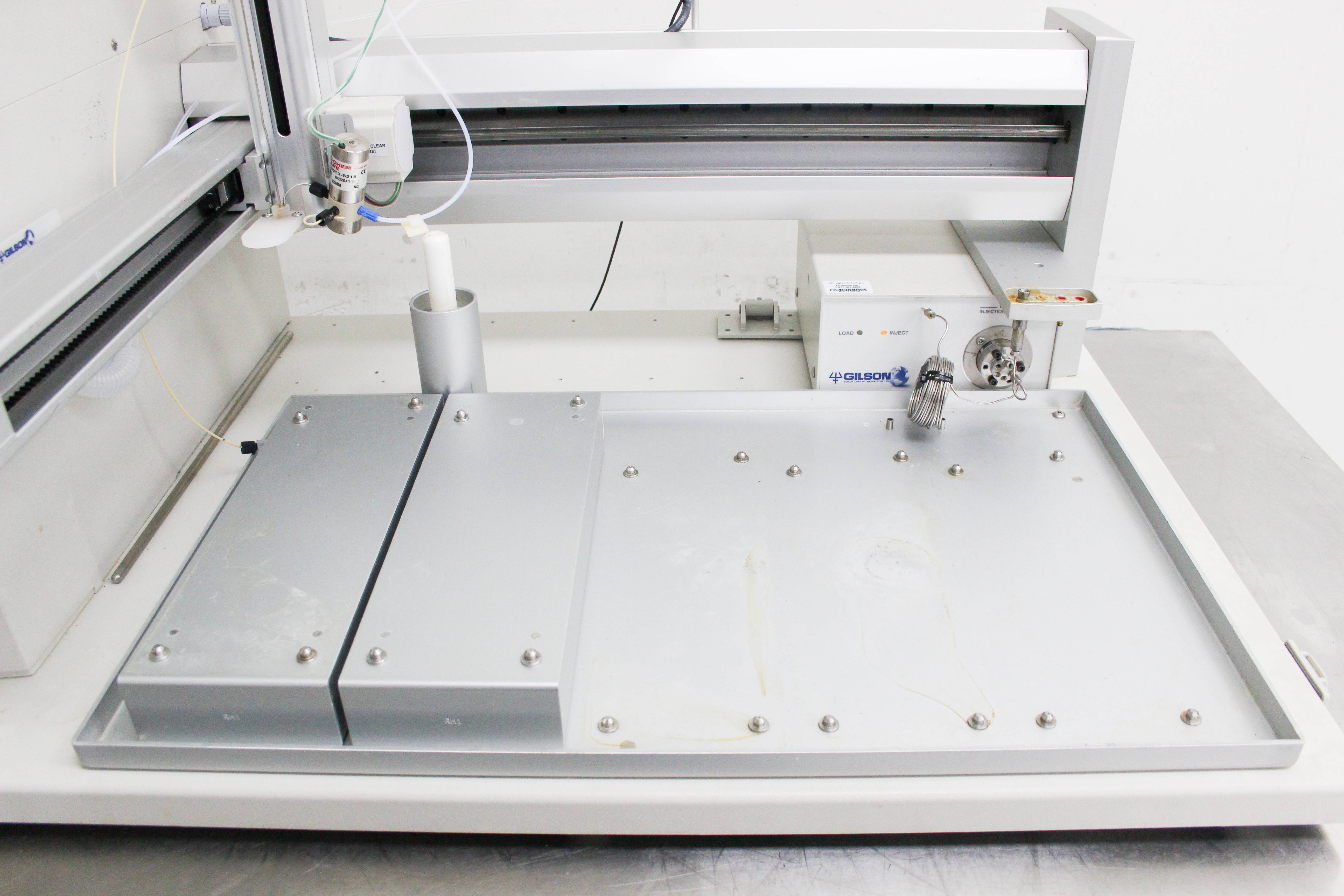

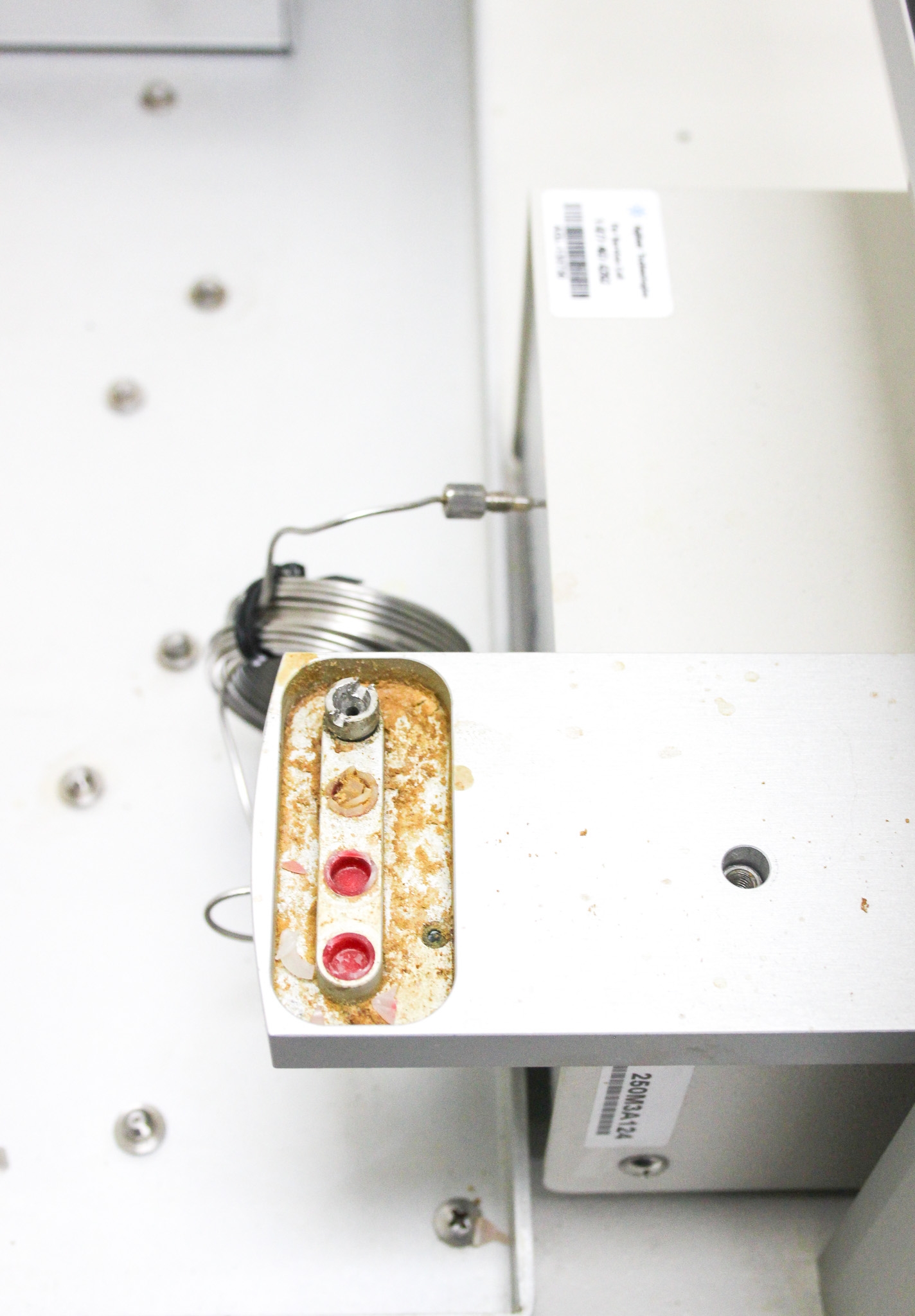

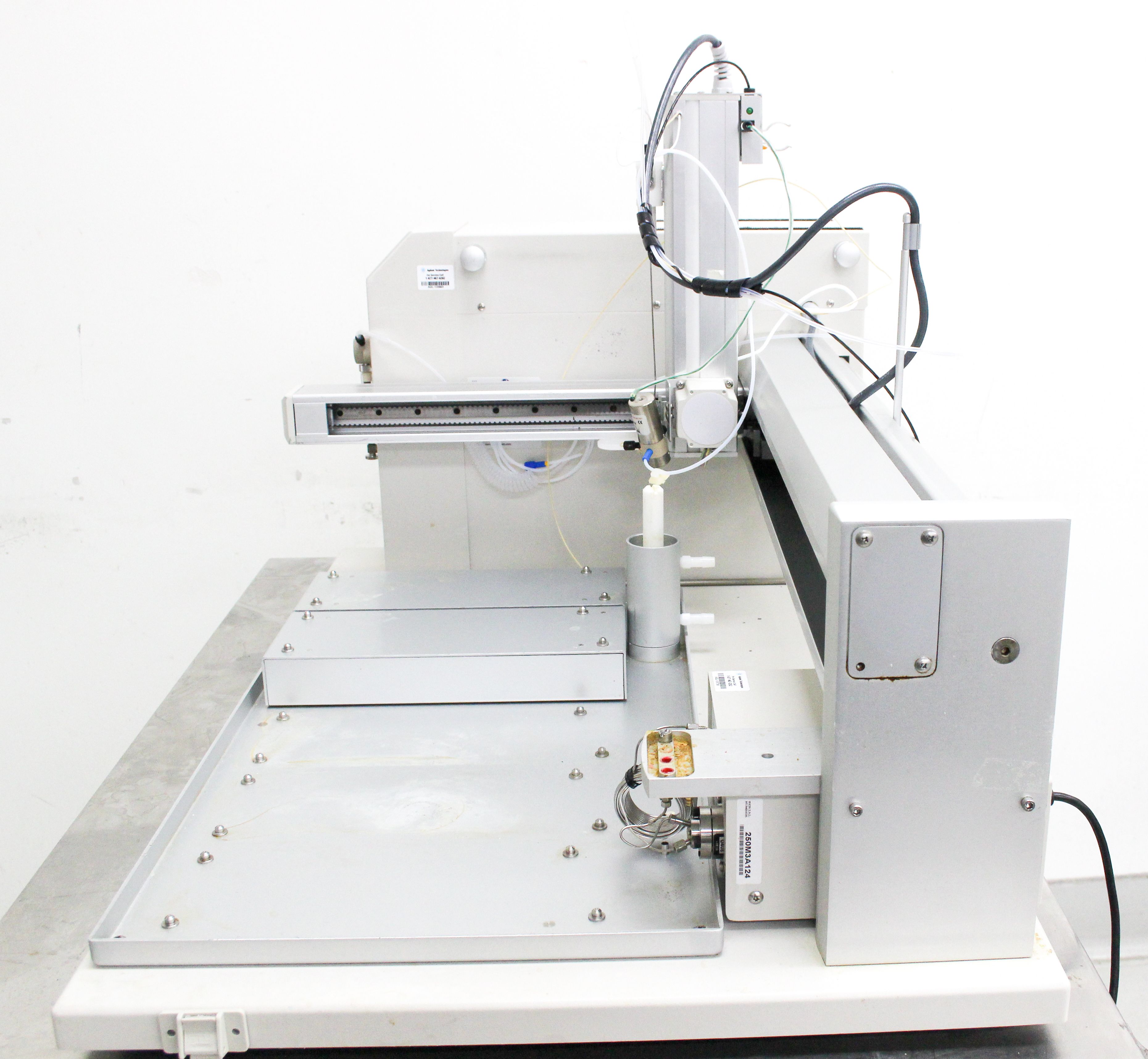

The Gilson Nebula Series 215 Liquid Handler with 819 Injection Module is a robust, used automated solution designed for high-throughput liquid handling tasks such as dilutions, mixing, and sample transfers. This unit, originating from the United States, powers on without errors and initializes successfully, but cannot be fully tested due to the absence of accompanying software. It features Dual Rail syringe drive technology, can accommodate over 330 racks, and manages a variety of probes for diverse applications within a lab setting. The 819 Injection Module, which is part of this equipment, provides efficient sample injection and supports high-pressure fraction collection and analytical tasks, minimizing carryover to less than 0.01%. The machine offers a 30-day warranty on parts and operates at a flexible voltage of 120V/220V and frequencies of 50Hz/60Hz. Despite visible signs of usage, it is rated in good condition and retains no known functionality issues.

Key Features

- High-throughput liquid handling capabilities

- Dual Rail syringe drive technology

- Supports 4 or 8 syringes for diverse applications

- 819 Injection Module for sample injection and fraction collection

- Handles flow rates above 20 mL/min with less than 0.01% carryover

Specifications

- Voltage: 120V/220V, Hertz: 50Hz/60Hz

- Dual rail syringe drive technology

- Capacity to accommodate over 330 racks

- Make-before-break rotor seal design

- 2-position high-pressure switching valve for fraction collection

- Punch strength capable of piercing thick septa and microplate mats

Weight

Imperial: 108.0 Pounds

Metric: 48.99 Kilograms

Shipping Dimensions

Imperial: 28.8 lb x 40.8 lb x 28.8 lb

Metric: 73.15 cm x 103.63 cm x 73.15 cm

Harmonized Code

8479.89.9499

Harmonized Code Details

Machines for assembling electric or electronic lamps, tubes, or valves or for manufacturing or hot working glass or glassware. The code fits because the liquid handler is considered specialized machinery used in laboratory settings for handling glass and plastic labware.

Comments 0

There are currently no public comments.